Week 4 Summary

For Week 4 of the HPS program, the participants were introduced to Design for Assembly (DFA) principles. One of the principles mentioned was "poka yoke", which implicates the importance of making the parts such that they can only be oriented one way. A few more points were brought up, including the necessity of access for the user when it came to disassembly of the product if a component was damaged. HPS participants were also strongly urged to consider things such as assembly tolerances, assembly fixtures, and wire and cable locations.

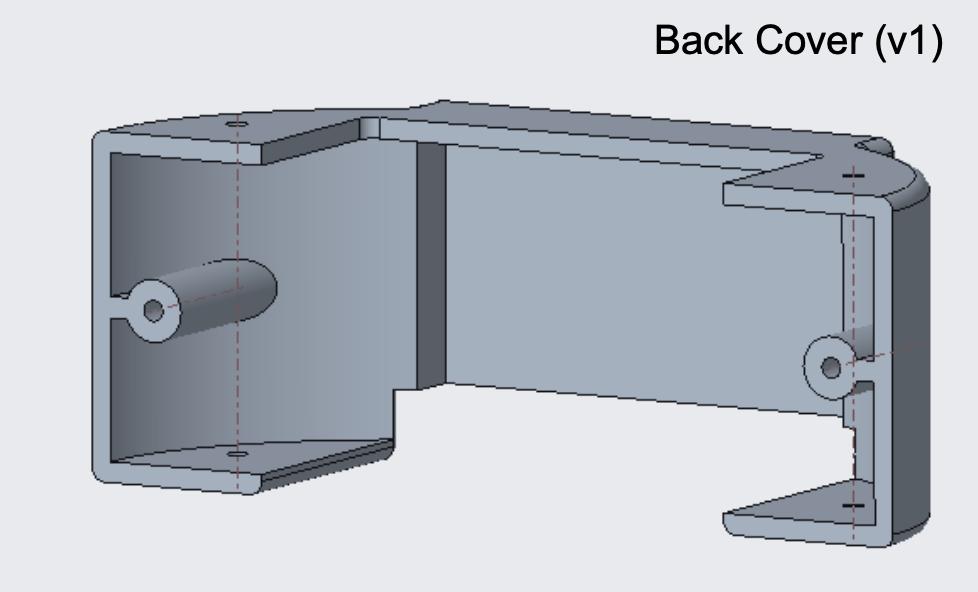

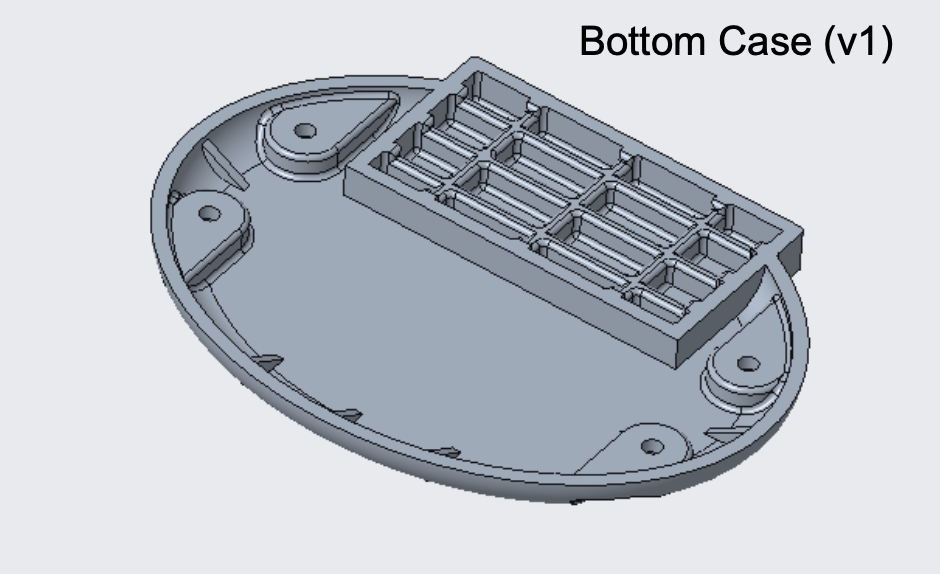

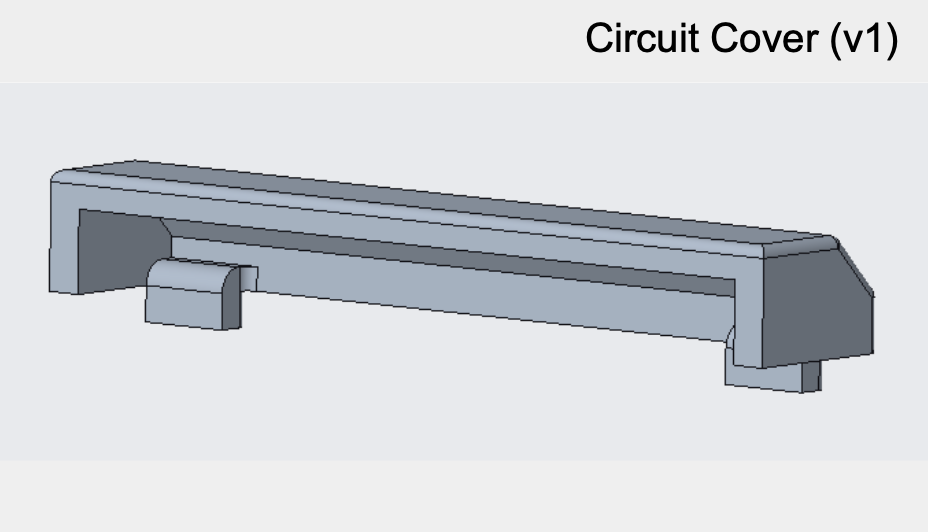

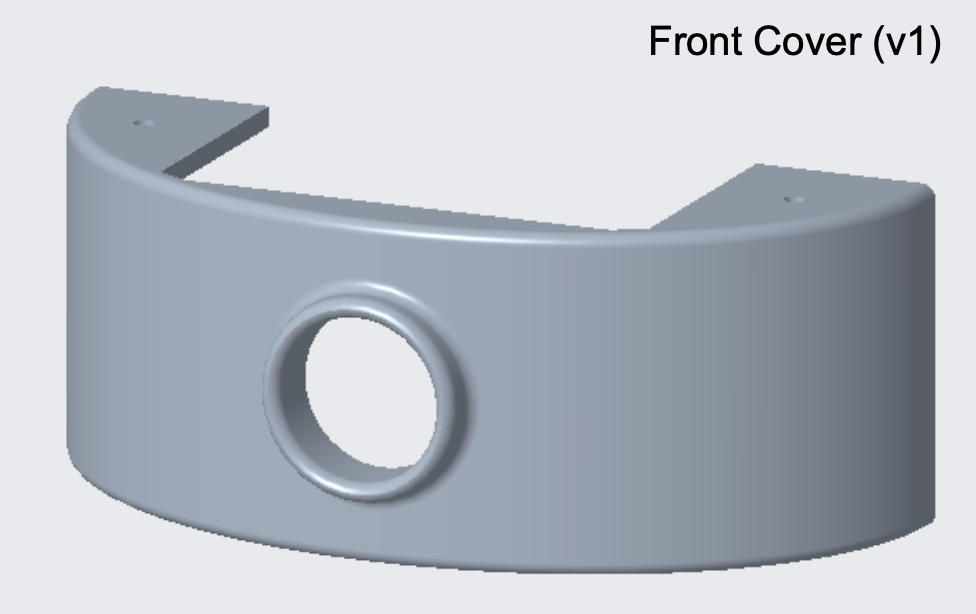

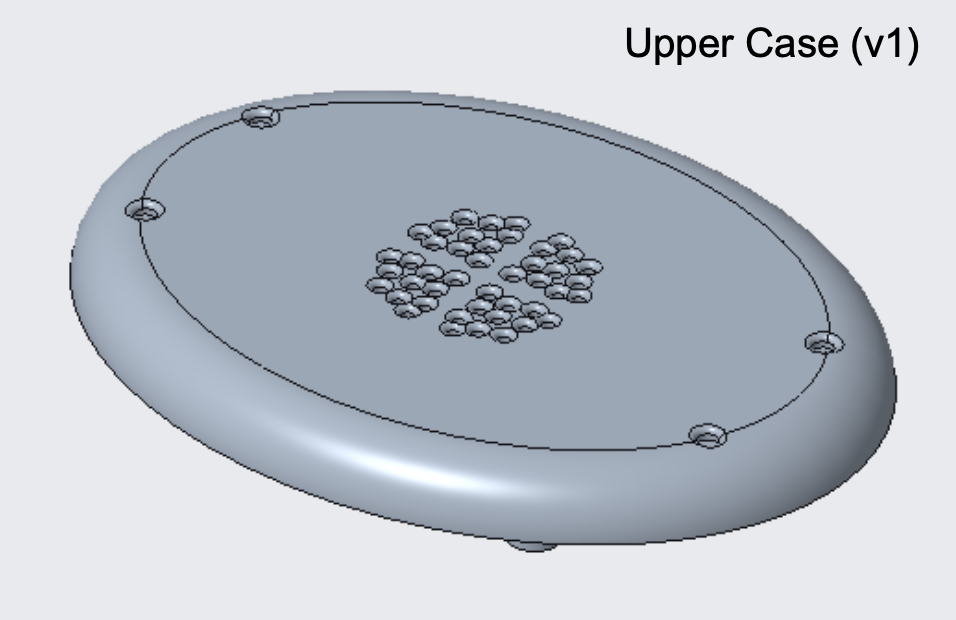

Revised Design (v1)

Based upon the lesson given by a Google instructor and my product advisor's feedback, I decided to include more parts for ease of access. Of course, the drawback is that I added parts to the product I was creating instead of reducing the number, but I also found this part increase necessary due to the change from interference fits to screws regarding assembly. Of the five parts, only the upper case and the front cover seem to disregard poka yoke, and considering the way each part is made and used within the assembly process, I believe it's fine if the consumer or manufacturer flips these parts upside down or turns them around.